Christmas by the Numbers: A Wasteful Wonderland?

It’s sad but true that Christmas is the most wasteful time of the year. Businesses and households in the UK generate much more waste at Christmas than any other time of year – from single use packaging to food leftovers, and everything in between.

But hope isn’t completely lost. By making a few small changes, we can all reduce the amount of waste we produce this Christmas time. In today’s blog, we outline some of the most shocking Christmas waste statistics in the UK, and share some top tips for reducing waste over the festive period.

Christmas waste statistics UK

Christmas Decoration & Tree Waste Facts

- A hefty 12,500 tonnes of Christmas decorations are discarded in landfill each year.

- In terms of Christmas fairy lights, we can expect to find the equivalent length of 70,000 miles thrown away this year.

- Approximately 40 million Christmas crackers will be chucked on Christmas Day.

- Tinsel is made of single-used plastic so cannot be recycled, meaning it will inevitably end up in landfill.

- UK citizens cut down 8 million trees for Christmas each year. Unfortunately, around 6 million of these will find their way into landfill.

- As they decompose, Christmas trees emit 100,000+ tonnes of methane gas, which is a key contributor to climate change.

Christmas Wrapping Paper Waste Facts

- We anticipate that around 108 million rolls of wrapping paper will be thrown away this Christmas. This equates to 75% of the overall wrapping paper sent to landfill each year.

- If you take out all the Christmas wrapping paper waste and lay it out flat, it would stretch to 238,855 miles – the same distance of the Earth to the moon.

- Most wrapping paper isn’t suitable for recycling. It often contains glitter, is laminated, or is extremely thin, which means it can only end up in landfill.

- 50,000 trees are cut down to make Christmas wrapping paper each year, greatly contributing to deforestation.

- UK households will use approximately 40 million rolls of sellotape to wrap their Christmas presents this year.

Christmas Packaging Waste Facts

- The majority of Christmas packaging waste ends up in the landfill. Frustrating, over 114,000 tonnes of recyclable packaging waste is wrongly placed in the general waste bin over the festive period.

- If you weighed the amount of plastic waste discarded during Christmas each year, this would equal the weight of 76,000 giraffes.

- When it comes to food packaging, we can expect to see 125,000 tonnes of waste thrown away this Christmas.

- 4,500 tonnes of tin foil will be used to cover leftover Christmas food in Britain this year. However, most tin foil is single-use, meaning it will find its way into landfill.

- We consume around 1 million mince pies each festive season, which creates an entire tonne of aluminium waste.

Christmas Food Waste Facts

- Wondering how much food is wasted at Christmas? Approximately 42 million plates worth of food waste will be generated this year.

- The average UK household spends £169 on food shopping in the lead up to Christmas. However, 7 in 10 people admit to buying more food than they actually need.

- 10 million turkeys are bought for Christmas dinners each year, but the majority of these will not be fully eaten.

- 263,000 entire turkeys will be thrown away this year, either from being spoiled, contaminated, or damaged.

- In terms of trimmings, 17.2 million sprouts, 7.1 million pigs in blankets, 9.8 million cups of gravy, and 9 million carrots will find their way into the bin.

- When it comes to after-dinner treats, Brits are expected to waste 7.5 million mince pies, 2 million kg of cheese, and 740,000 portions of Christmas pudding this year.

Tips for minimising waste over the festive period

One of the best ways to reduce waste this Christmas is to be mindful of what you’re purchasing. Think about whether you actually need to buy every item on your list, and consider how your actions may impact the environment. Some of our specific tips for reducing waste over the festive season include:

Minimising Christmas Decoration & Tree Waste

- Switch to zero waste Christmas decorations instead of tinsel this year, such as reusable festive garlands and colourful bunting.

- If you have unwanted decorations that are still in working condition, take them to a charity shop instead of throwing them in the bin.

- Replant your Christmas tree in your garden so you can reuse it again next year.

- Alternatively, you can take your Christmas tree to your household waste recycling centre for shredding and composting.

- If you’re opting for an artificial tree this year, dispose of it in the small appliance or plastic reuse containers at your local recycling centre.

Lowering Wrapping Paper & Packaging Waste

- Try eco-friendly wrapping paper alternatives this Christmas, such as brown paper with string and sprigs of holly.

- Ask for and give items to others that use less packaging. Consider making some homemade gifts or purchasing from a sustainable packaging company.

- Check whether your wrapping paper is recyclable before throwing it away. If it holds its shape when you scrunch it into a ball, it is recyclable. If it springs back open, it cannot be recycled.

- Remove any plastic bows and ribbons before recycling your wrapping paper. These can be easily reused for future wrapping.

- If you use glitter for your Christmas packaging, do not tip it down the sink as it can pollute our landfills and oceans. Instead, purchase eco-friendly glitter that can be stored and reused again.

Reducing Christmas Food Waste

- Plan ahead when purchasing food for Christmas. Think carefully about what you will realistically eat over the festive period and don’t buy more than you need.

- Buy loose fruit and vegetables rather than larger, cheaper bags that you are unlikely to get through.

- Get inventive with your Christmas leftovers and think about how you could reuse your trimmings in sandwiches, soups, and stocks.

- If you find yourself with extra food that your family is unlikely to eat, freeze it for a later date.

- Invest in a compost bin for disposing of your peelings and leftover fruit and vegetables.

Wrapping up

Christmas is a time for giving, which includes making a positive contribution to our environment. By choosing more sustainable options and being mindful of your consumption, you can give the gift of a greener planet this festive period.

McCarthy Marland can help UK businesses and households reduce waste this Christmas. Our expert team can handle all your festive waste management needs – from skip hire and wheelie bins, to flexible Christmas waste collections. Get in touch today to discover how we can help support you this festive season.

Tips for Asbestos Disposal

Coming across asbestos can be daunting; it doesn’t matter if you are a homeowner doing DIY or a contractor working on a commercial job; asbestos can put a hold on any work, so getting it sorted effectively and efficiently is important.

Below, we will discuss the different types of asbestos, what to do if you come across it and what you should do to get rid of it.

What is asbestos & what are the two categories of asbestos?

Asbestos is a term used for a group of naturally occurring mineral fibres. These fibres are resilient against heat and chemicals, strong, and neither dissolve in water nor evaporate. Asbestos fibres are categorised into two main sub-groups:

1. White Asbestos

Also known as chrysotile, it is the most common type of asbestos used, its flexible fibres were ideal for roofing, flooring, and insulation. Its resistance to heat made it common in brake linings and fire-resistant textiles, significantly utilised due to perceived lower health risks than other forms.

2. Brown and Blue Asbestos

Two types of asbestos, known as amphiboles, are said to be the more harmful asbestos due to their fibre’s effects on the lungs. They are known for their insulation and fireproofing applications

What are the dangers of asbestos?

Whilst it is possible to have asbestos on your property and not be in danger, it has to be said that there is no safe level of asbestos to inhale.

Any exposure to asbestos can cause long-term and life-shortening health issues, and the risks of developing these health issues grow with more and more exposure to the hazardous material.

Breathing in asbestos at high concentrations or over a sustained period mainly affects the lungs with a disease called Asbestosis, where it becomes difficult to breathe, and the heart can become inflamed and enlarged. Asbestosis is not instant and can take many years to develop; you can also have a higher risk of cancer. If you are exposed to asbestos in low concentration but over a sustained period, you can suffer the thickening of the lung lining, which, whilst not fatal, may make you more susceptible to lung cancers.

When was asbestos banned in the UK?

Due to the health issues associated with asbestos, it is banned in the UK. This started with the ban on Brown and Blue asbestos in 1985 and then on White asbestos in 1999.

Why was asbestos used so much?

Asbestos was used so much because of its inherent properties. Not only is it cheap to make, but it is strong, offers great heat insulation and is resistant to fire, water, and chemical substances.

As a building material, it seemed the perfect choice. It has been used in various applications, from insulation for boilers and pipes to adding cement to create roofing sheets.

Before 1999, using asbestos as a building material was commonplace, and this means that we are still dealing with it today

How many buildings have asbestos?

It was thought to be a great building material and was first used in the UK around the 1870s up until it was banned in 1999. There are an estimated 1.5 million buildings that are thought to contain some asbestos still. This includes homes and many public buildings, such as schools and hospitals.

What should I do if I find asbestos?

When intact and undisturbed, asbestos-containing materials present minimal risk. However, the danger escalates when these materials are damaged, releasing asbestos fibres into the environment.

This release primarily occurs during activities such as demolition, building repairs, maintenance, and, notably, do-it-yourself (DIY) projects within buildings that contain asbestos. It is during these times that you must exercise utmost caution to prevent exposure.

Exposure to asbestos can occur in various ways. Inhalation of airborne fibres is the most common route, posing significant health risks. Although less common, individuals may ingest asbestos fibres if they enter the soil or water supply. This could happen through erosion from materials such as asbestos-cement. Nevertheless, it’s important to note that, to date, ingested asbestos fibres have not been conclusively linked to health issues, according to existing evidence.

The likelihood of exposure is significantly heightened for those working in areas with a high risk of disturbing asbestos-containing materials, such as demolition, asbestos removal, or building maintenance. In such scenarios, following stringent safety protocols to minimise airborne fibre release is crucial.

What should you do if you are exposed to asbestos in your home?

If you encounter intact asbestos materials that are not likely to be disturbed, they generally do not pose a threat. However, should you come into contact with asbestos fibres, immediate steps should be taken to minimise exposure. Avoid any actions that could make the fibres airborne—such as shaking out clothes or brushing off dust—as this increases the risk of inhalation.

If fibres are present on your skin or clothing, carefully wipe them off with a damp cloth using a gentle patting motion. Any contaminated clothing should be carefully removed (avoid pulling over the head) and sealed in a bag along with the used damp cloth. It is then essential to seek advice from your local authority regarding properly disposing of these materials.

In the event of health concerns following exposure to asbestos, consultation with a healthcare provider or contact with NHS 111 for guidance is advised. Such measures ensure that potential risks are addressed swiftly and appropriately, safeguarding your health and well-being.

How to dispose of asbestos?

Disposing of asbestos takes specialist equipment and techniques to reduce exposure to harmful fibres that do not go into the air, causing harm to the person disposing of the asbestos and any people in the surrounding area.

The only safe way to dispose of asbestos is to hire a specialist removal company to ensure that all asbestos and any asbestos-contaminated materials are cleared away from the area.

Specialist teams use protective overalls and ventilators to stay safe whilst working and will douse the asbestos in water before starting working to stop fibres from becoming airborne. They will continue to use water sprays whilst working in batches until they can get the asbestos into the specialist skip and ready to be transported away.

What happens to asbestos once it has been disposed of?

All asbestos is classed as a hazardous material and is legally required to be disposed of in a way that ensures it is disposed of at minimal risk to the public and its surroundings.

All asbestos disposed of is taken to a special asbestos landfill site. These sites are clearly signposted, away from any area that the general public could stumble across. All containers housing asbestos are clearly bagged and labelled to ensure they are not accidentally opened.

Call in the asbestos specialists

If you are in the South West and discover what you think is asbestos, our qualified team of specialists can help you legally and safely dispose of it. So you don’t have to worry about coming into contact with it and breathing in any of its harmful fibres.

To find out more about our asbestos disposal service or any of our other hazardous waste disposal services, you can reach out to your local team at Gloucestershire: 01453 701230 Bristol & Bath: 0117 941 2555 Somerset: 01458 274654, or simply email customerservices@mccarthymarland.co.uk and one of our specialists will help talk you through the process.

Did You Know? Weird and Wonderful Facts About the World of Waste!

We all throw things away, but have you ever stopped to think about the fascinating world behind that discarded banana peel or plastic bottle? The waste management industry is more than just garbage trucks and Skips – it’s a complex ecosystem overflowing with surprising facts and innovative solutions. So, let’s dig (figuratively, of course) into some fun waste facts!

14 million tonnes of municipal waste was sent to UK landfill in 2021. 6.8 million tonnes of this was biodegradable waste i.e. greenhouse gas producing. DEFRA has set a target for the ‘near elimination’ of biodegradable waste to landfill by 2028! Great news for the Environment!

Who is DEFRA? Defra – Department for Environment Food and Rural Affairs.

- Half of all food produced globally goes to waste! That’s a staggering 3,000 pounds of food chucked every second in the US alone.

- Love your plastic water bottle? Well, it might take up to 1,000 years to decompose!

- The Great Pacific Garbage Patch isn’t just a legend. This monstrous floating island of plastic trash in the Pacific Ocean weighs a whopping 80,000 tons, and it’s growing.

- Glass might seem like a recycling winner, but it can take over a million years to decompose! Luckily, it’s also infinitely recyclable, so go ahead and crush those bottles with gusto!

- E-waste, the fastest-growing waste stream, is full of hidden treasures. Recycling just one ton of smartphones can recover gold worth more than 120 times the amount mined from a ton of rock! Talk about turning trash into treasure!

- Biogas made from food waste can power homes and fuel cars. So, that discarded apple core could take you on a road trip one day! Visit GENeco to find out more as this is exactly what they do! https://www.geneco.uk.com

These are just a few of the many fascinating facts that lurk in the shadows of the waste industry. So, the next time you toss something away, remember the journey it takes and the impact it has. Maybe you’ll be inspired to reduce, reuse, or recycle with a newfound respect for the hidden world of waste management!

Our guide to Waste Management

Waste management, an often overlooked aspect of our daily lives, plays a crucial role in protecting our environment and fostering sustainable practices. It encompasses the collection, transportation, processing, and disposal of waste materials, ensuring their proper handling and minimising our impact on the environment.

Different types of Waste Management

Waste management encompasses a wide range of strategies and techniques to effectively manage waste streams. Here are some key aspects of effective waste management:

Waste Segregation: The first step in waste management is segregation, separating recyclable materials from general waste. This allows for efficient recycling and significantly reduces the volume of waste destined for landfill.

Recycling: Recycling is the process of converting waste materials into new products, reducing the need for extracting raw materials from the environment. This not only conserves resources but also minimizes energy consumption and greenhouse gas emissions.

Composting: Composting is the process of organic matter breaking down into nutrient-rich soil amendments. This method diverts food waste from landfills, preventing methane emissions and producing a valuable soil conditioner.

Waste to Energy: A facility that recovers the energy within the waste by combusting the leftover materials to create steam in a boiler, which is converted into electricity.

Hazardous Waste Management: Hazardous waste requires specialised handling and disposal due to its potential to harm human health and the environment. Proper hazardous waste management protects public safety and prevents environmental contamination.

How Much Does it Cost to Dump Commercial Waste in the UK?

The cost of dumping commercial waste in the UK varies depending on the type of waste, quantity, and disposal method. For general waste this typically costs from £80 to £150 per tonne. Recycling and composting services also have associated fees, but they often provide cost savings.

Some waste types can even be free of charge to tip in such as scrap metal. At McCarthy Marland’s disposal sites we can take commercial waste to be tipped in. If you would like to know more about our prices for tipping please get in touch!

Tips for Minimising Waste Costs

Conduct a waste audit: Identify the types and quantities of waste your business generates to develop a targeted waste reduction plan.

Implement recycling and composting programs: Encourage employees to segregate recyclable materials and compost food waste.

Purchase reusable products: Reduce disposable items, such as water bottles, cups, and utensils, to minimize waste generation.

Fix and repair equipment: Prolong the lifespan of equipment to reduce waste from discarded items.

Choose eco-friendly packaging: Opt for recyclable or compostable packaging materials to reduce the environmental impact of waste disposal.

Efficient waste management is not just about minimising environmental impact; it’s also about saving money and reducing operational costs, such as choosing a local Waste Company to reduce transport costs and emission’s. By implementing sustainable practices and engaging employees in waste reduction efforts, businesses can reap the environmental and financial benefits of effective waste management.

If you would like to speak to a member of our team on to how to improve your waste management get in touch today! 0117 941 2555 or email customerservices@mccarthymarland.co.uk

McCarthy Marland: Transforming Plastic Waste into Reusable Resources

In today’s world, reducing our reliance on single-use plastics is crucial for environmental sustainability. At McCarthy Marland we are committed to recycling plastic waste and transforming it into valuable resources through an efficient and sustainable process.

Step 1: Collection and Transportation

McCarthy Marland collects plastic waste from various sources, including homes, businesses, and industrial facilities. The collected plastic is transported to our Waste Transfer Stations in either Bristol, Gloucester, Somerton, or Oxford, where the journey towards recycling begins.

Step 2: Manual and Mechanical Segregation

Upon arrival at one of our Waste Transfer Stations, the plastic waste undergoes a thorough process of manual and mechanical segregation. Experienced staff sort through the waste, removing non-recyclable items like metal, glass, and contaminated materials. Mechanical separators then further refine the plastic stream, separating different types of plastics based on their density and physical properties.

Step 3: Baling and Bulking

The sorted plastic is compressed into large bales to maximise storage efficiency and facilitate transportation to recycling facilities. These bales are then transported to our processing partners, who further break down the plastic into granular or pelletized form.

Step 4: Reprocessing and Upcycling

At these processing facilities, the plastic undergoes a series of chemical and mechanical treatments to transform it into new products. PET bottles, for instance, can be recycled into new bottles, fibers for clothing or carpets, or even food-grade packaging. HDPE containers can be repurposed into new containers, garden furniture, or construction materials.

Step 5: Market Placement and End Use

The recycled plastic pellets or flakes are then distributed to manufacturers who use them to create a wide range of products, reducing the demand for virgin plastics and their associated environmental impact.

By partnering with recycling facilities and manufacturers, we contribute to a circular economy, where plastic waste is not discarded but given new life, reducing our environmental footprint and fostering a more sustainable future.

What are compaction systems used for?

Compactors and Balers are great for customers who generate high volumes of dry packaging like cardboard, paper, and plastics.

When a company starts to create high volumes of waste, compactors can become a great option and sometimes essential for companies for several reasons:

Cost savings: Waste compactors can significantly reduce waste volume, which in turn reduces the frequency of waste collection and disposal. This saves companies money as they require fewer waste collection services.

Space efficiency: By compacting waste, companies can drastically reduce the amount of storage space needed for waste before disposal. This is especially important for businesses with limited space, as it allows them to utilise their available space more efficiently.

Environmental benefits: Waste compactors contribute to a more sustainable environment. By reducing the volume of waste, they help to minimise the amount of space needed in landfills. This is crucial as landfills contribute to pollution and can have negative impacts on local ecosystems. Additionally, compacting waste leads to fewer vehicles on the road for waste collection, resulting in reduced emissions and fuel consumption.

How much weight can a compactor container hold?

When we draft a savings analysis for a customer the standard calculation is 4:1 as most compactors can compress waste into a space a quarter of is original size. The standard way for calculating how much weight a compactor container can hold is = (container size X 580 / 2000= Total Weight in Tons).

We offer 35-yard Compactor Containers therefore 35 x 580 / 2000 = 10 tonnes (roughly) is how much our containers can hold.

This calculation is based on the fact that most waste is compressed into a compactor container at a rate of between 500 and 600 pounds per cubic yard multiplied by the amount of cubic yards in a container and divided by the number of pounds in a yard.

What waste can go into a compactor container?

- Dry General Waste

- Cardboard

- Plastics

Overall, waste compactors help companies save money, make their waste management more efficient, and contribute to a greener and more sustainable environment.

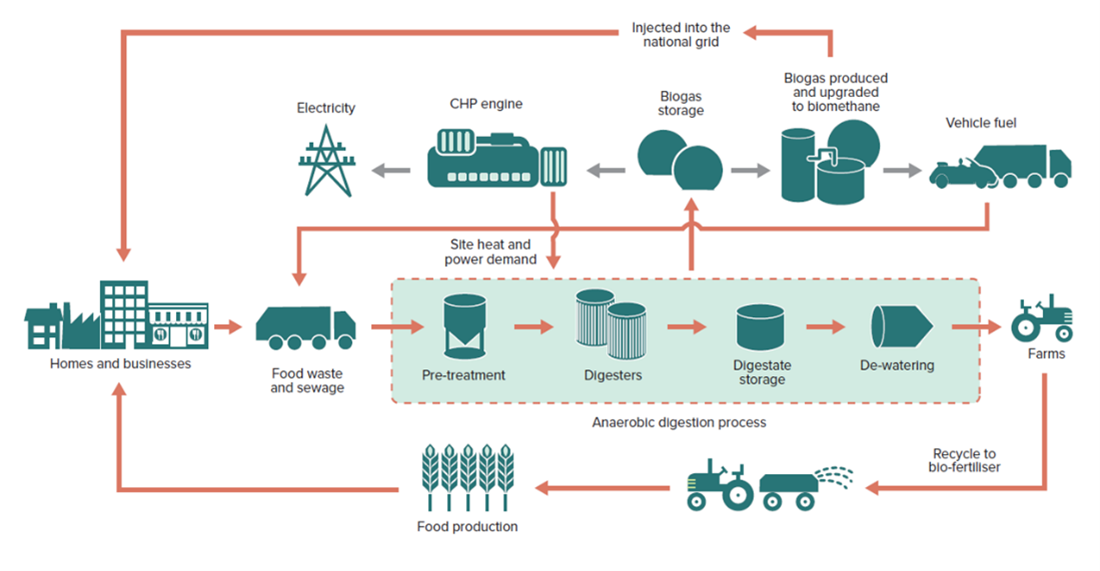

How does your food waste get converted into energy?

Part of McCarthy Marland’s company model involves collaborating with subcontractors. One example is GENeco, who share our company values of reusing waste to our environment’s advantage. We firmly believe that waste should not end up in landfills; instead, it should be processed and reused in the most environmentally friendly manner. At McCarthy Marland, we are committed to recycling or converting our waste into energy. GENeco perfectly aligns with our goals as they also recycle and reuse all their waste where possible to convert it into energy.

But how do they do this?

Biomethane has the same composition as methane derived from fossil fuels and can be used as a sustainable substitute for natural gas.

Biomethane is produced at Bristol sewage treatment works by upgrading biogas produced from anaerobic digestion – a completely natural process in which micro-organisms break down biodegradable material in the absence of oxygen.

Biomethane is used as a renewably sourced and sustainable substitute for natural gas in the local distribution network across Bristol. GENeco supply the national grid with enough gas to supply thousands of local homes and ensure our sewage treatment works is energy self-sufficient.

How it works

- Food waste is treated and pumped into a series of anaerobic digesters. The waste is heated to 32 – 42°C and kept in the digesters for 12 to 18 days. During this time, micro-organisms break down the biodegradable material in the absence of oxygen to produce methane rich biogas. At this point, the biogas contains around 60% methane.

- The biogas produced from the digesters then enters the gas to grid plant. The first stage upgrades the biogas to biomethane (~98%; 1.5% nitrogen).

- A bioscrubber removes gaseous impurities, such as carbon dioxide and hydrogen sulphide. Meanwhile the carbon filters produce virtually odour free emissions to the air.

- A small volume of propane is injected into the biomethane. This enriches the gas to natural gas quality and calorific value.

- The end product, enriched biomethane, is analysed and undergoes strict quality controls before being fed into the local gas distribution network.

- GENeco also use biomethane to power their waste collection fleet. Using biomethane in this way reduces the amount of harmful particulate matter vs diesel equivalent engines.

How to dispose of Hazardous Waste

Hazardous waste isn’t as uncommon as you might think, it can be found in everyday household items such as cleaning products and batteries. Chemicals, fuels and oils are often produced by businesses across the UK, and failing to dispose of this waste in line with compliance can cause significant harm to the environment and human health.

According to the Environmental Agency, the hazardous waste market has a total volume of 5 million tonnes of waste handled in the UK each year. Not handling hazardous waste correctly can result in large fines and even imprisonment depending on the severity of the situation at hand.

Thankfully, disposing of hazardous waste has become a relatively straightforward process over the years, making it easier for businesses to dispose of their waste and leave no excuse to pollute the environment around them. Learning how to dispose of hazardous waste correctly is the first step.

The rules around hazardous waste

Hazardous waste can not be disposed of in landfills or waste bins like general waste. Specific processes are in place to ensure the safety and wellbeing of everyone involved, which is why it is important to know that you mustn’t treat hazardous waste unless you are qualified to do so and have the appropriate facilities available.

Examples of hazardous waste include:

- Chemicals (e.g. brake fluid or cleaning products)

- Asbestos

- Solvents

- Batteries

- Hazardous waste containers

- Oils (e.g. car oil)

- Pesticides

- Items that contain ozone-depleting substances (e.g. aerosols, fridges, air conditioners)

The journey to hazardous waste disposal

Once you have indicated that your waste is hazardous, it becomes your legal responsibility to keep it safe before disposal. Keeping hazardous waste stored away while you wait to dispose of it is an essential part of the process. It must be stored in sealed containers in a separate area but close to where you would normally deal with waste.

Hazardous waste isn’t something you can take anywhere, you can only dispose of it at authorised sites where experts can collect and handle the materials for you. A classification code and the details of the hazardous materials are usually required so experts know of the risks associated with

It’s important to keep in mind that local landfills may not accept certain types of hazardous waste, particularly if it’s corrosive or flammable. Thankfully, there are still plenty of hazardous materials that can be recycled, including light bulbs, cleaning fluids, oil-based paints, garden chemicals, automobile fluids, adhesives, batteries and more. Each recycling centre will have its own rules and regulations regarding the disposal of hazardous waste, so make sure you get in touch before showing up.

While it might seem difficult to dispose of hazardous waste safely and with the environment in mind, it’s more important to consider that non-compliance can result in serious harm to both the environment and humans. Many penalties can occur if hazardous waste is not handled correctly, but following procedures can make the disposal process much easier.

At McCarthy Marland, we offer comprehensive hazardous and technical waste solutions that are compliant with all legislation. Get in touch with us today to find out more about how we can help you.

Addition to fleet

New Bell B30E dump truck delivered and put straight to work at our Somerton facility.

New Machinery fitted for our Transfer Station

We have now installed a new Baughan waste sorting line at Albert Quay in Bristol. This new technology will significantly increase the amount of recyclable material we can recover from the waste we handle in Bristol.